Chains

Our range of Drop Forged and Pressed K Chains click below to view information.

DROP FORGED CONVEYOR CHAIN (FORK LINK CHAIN)

QUALITY CONTROL

Quality Control procedures include the following:

• Raw material analysis is received with steel suppliers certificate.

• Regular dimensional checks take place

• Pitch tolerance is checked every 1000 metres.

• Hardness checks are carried out on 1 part in 1000 components.

• Samples of each batch are crack detected.

If the customer requests it, 100% magnaflux crack detection can be

carried out.

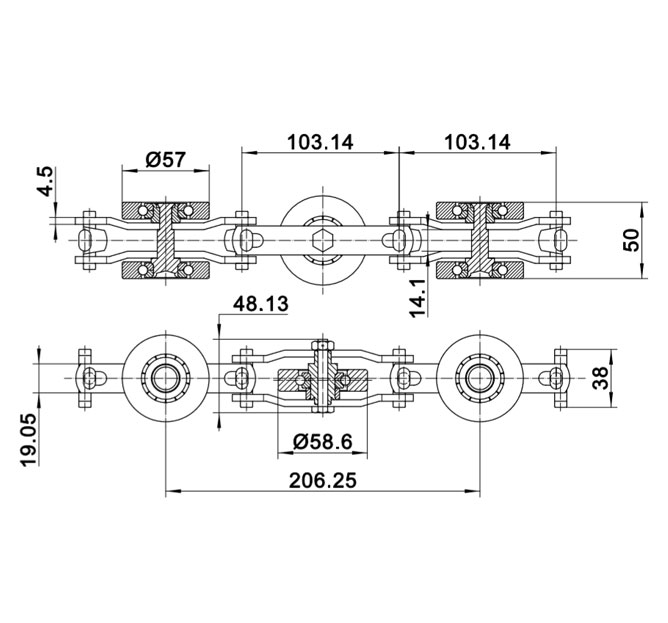

DROP FORGED RIVETLESS CHAIN

Drop forged rivetless chain is used extensively for trolley conveyors, drag conveyors and flight conveyors. It is an ideal chain for these applications due to its high strength to weight ratio, its ability to flex in both the horizontal and vertical planes, and the overall simplicity of the chain i.e. it comprises three components which can be assembled and disassembled by hand without the use of tools.

There are basically two patterns of chain, the regular pattern and the Xtype pattern. The regular pattern tends to be used in the heavier range of chain in drag and flight conveyors operating in materials that would tend to pack in chain joints. The X-type pattern is now extensively used in overhead trolley conveyors and its design gives increased strength and the ability to flex transversely on a smaller radius. The X-type chain is manufactured in sizes 348, 458, 658 and 678. These chains conform with BS6849(1987) and 1S06973(1986).

PRESSED K CHAINS

K458 chain has the following features:

• Accurate pitch –

All links are accurately punched and pins fully machined.

• Induction hardened connecting pin.